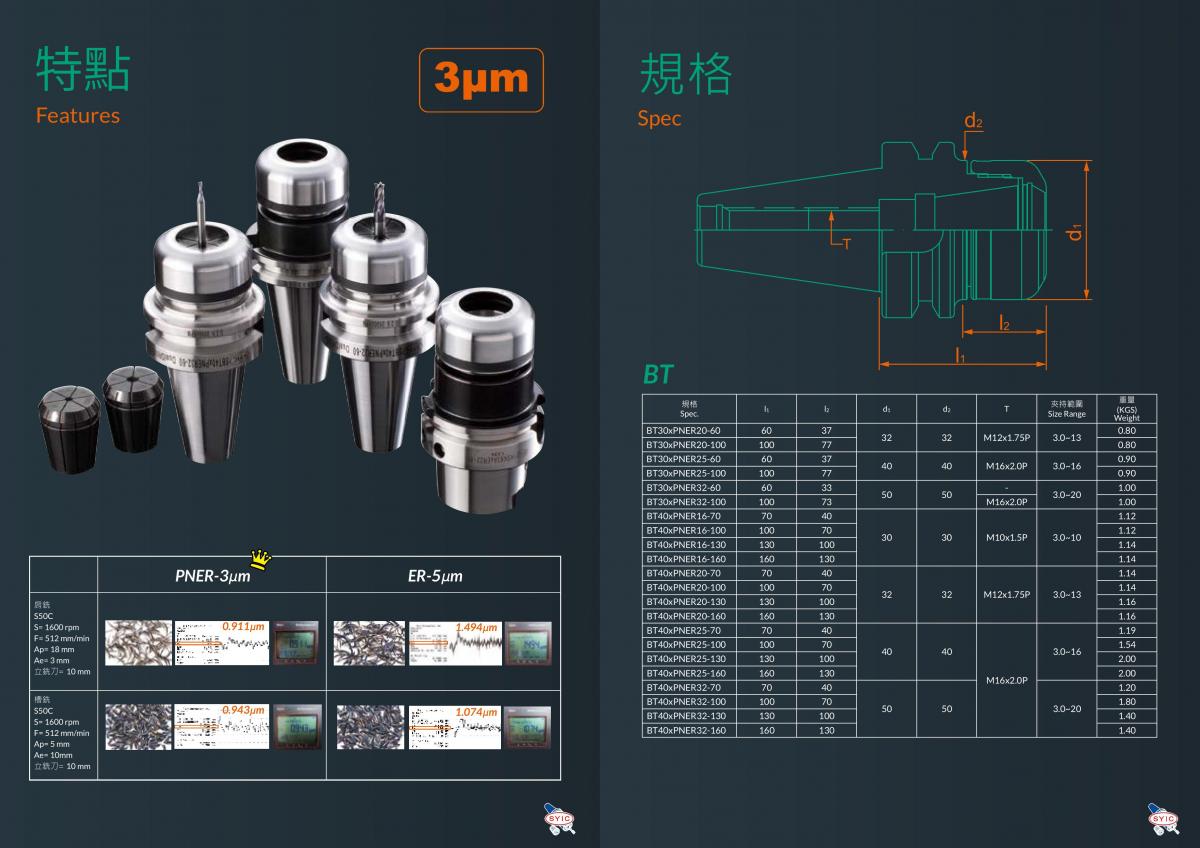

一、正河源SYIC PNER刀柄的特点:

1.双面***

2.锥面真圆度<0.6μ

3.标准动平衡G2.5 36000rpm

4.表面粗糙度Ra<0.2μ

5.建议夹持柄径公差H7

6.夹持精度达3μ(4D处),钻孔、铰孔、铣削、攻牙等加工,可达到的精度

二、正河源SYIC PNER刀柄的价值:

1.PNER刀柄及PNER筒夹可以提升加工精度,减少昂贵的再加工时间;

2.延具寿命,使机台主轴的精度能维持更久;

3.降低整体生产成本,提高生产效益。

4.特别针对小孔攻牙和钻孔,精密加工等方面会产生直接良好效果

因此,实现***率和高质量的加工需求,Pro-Line系列刀柄和筒夹是你的选择!

常用BT刀柄规格如下:

SBT30-PNER16-50

SBT30-PNER16-100

SBT30-PNER20-60

SBT30-PNER20-100

SBT30-PNER25-60

SBT30-PNER25-100

SBT30-PNE***-60

SBT30-PNE***-100

SBT40-PNER16-70

SBT40-PNER16-100

SBT40-PNER20-70

SBT40-PNER20-100

SBT40-PNER25-70

SBT40-PNER25-100

SBT40-PNE***-70

SBT40-PNE***-100

SBT40-PNER40-70

SBT40-PNER40-100

SBT50-PNER16-70

SBT50-PNER16-100

SBT50-PNER20-70

SBT50-PNER20-100

SBT50-PNER25-70

SBT50-PNER25-100

SBT50-PNE***-70

SBT50-PNE***-100

SBT50-PNER40-80

SBT50-PNER40-100

常用PNER筒夹规格如下:

PNER16-3

PNER16-4

PNER16-5

PNER16-6

PNER16-7

PNER16-8

PNER16-10

PNER20-3

PNER20-4

PNER20-5

PNER20-6

PNER20-7

PNER20-8

PNER20-9

PNER20-10

PNER20-11

PNER20-12

PNER20-13

PNER25-3

PNER25-4

PNER25-5

PNER25-6

PNER25-7

PNER25-8

PNER25-9

PNER25-10

PNER25-11

PNER25-12

PNER25-13

PNER25-14

PNER25-15

PNER25-16

PNE***-3

PNE***-4

PNE***-5

PNE***-6

PNE***-7

PNE***-8

PNE***-9

PNE***-10

PNE***-11

PNE***-12

PNE***-13

PNE***-14

PNE***-15

PNE***-16

PNE***-17

PNE***-18

PNE***-19

PNE***-20

PNER40-6

PNER40-7

PNER40-8

PNER40-9

PNER40-10

PNER40-11

PNER40-12

PNER40-13

PNER40-14

PNER40-15

PNER40-16

PNER40-17

PNER40-18

PNER40-19

PNER40-20

PNER40-21

PNER40-22

PNER40-23

PNER40-24

PNER40-25

PNER40-26