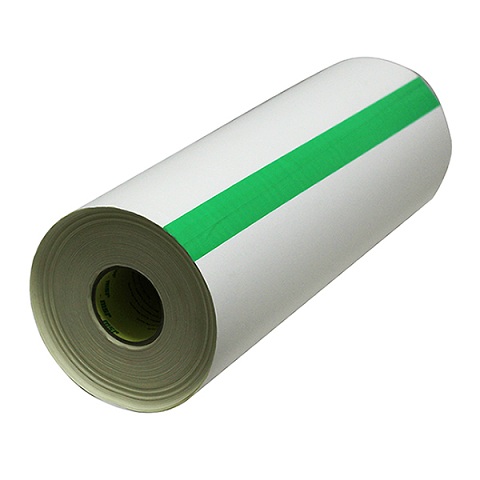

Jsw-615 hot melt film can be used to bond a variety of substrates, and can handle the most difficult bonding applicati*** in all walks of life, including some plastics that are difficult to bond. It is not only widely used in traditional industries, such as mobile phones, tablet computers, camera windows, and mobile power supply. 615 hot melt film is increasingly used in watch industry, lighting industry and new energy and new materials. 615 hot melt film has many advantages: adjustable opening time, long-term reliability, moisture resistance and chemical resistance. JSW company has the core technology of electronic 615 hot melt film. The products h***e good initial adhesion, high final shear strength, excellent vibration resistance and weather resistance, and can bond almost all materials of glass, plastic and metal.

The above is a brief introduction of 615 hot melt film. For detailed data, please go to the download window of jinshengwei official website. The following is the informal information of 615 hot melt film for reference only.

Not only can it be used for bonding and fixing various TP screens of electronic products, 615 hot melt film can also be used for sealing certain window components and other occasi*** requiring fixing and connection. The products bonded with 615 hot melt film are resistant to chemical reagents, solvents and alkalis, but warm can soften them. Solidification is insoluble in water, glycerin, etc., but can absorb alcohol swelling and produce stress cracking. 615 hot melt film and other harsh climates h***e good weather resistance. It has excellent atmospheric aging resistance. After 4 years of natural aging test, its sample has a slight decrease in weight, tensile strength and light tran***ittance, a slight yellowing in color, no ***ious decrease in craze resistance, a slight increase in impact strength, and almost no change in other physical properties of 615 hot melt film.

Any modified 615 hot melt film can only form a good adhesive layer on a suitable surface. The general treatment method for the bonding surface is: for the surface with low requirements or relatively clean surface, the oil stain can be removed by solvent such as alcohol and acetone, and the bonding can be carried out after the cleaning agent volatilizes. The chemical treatment method of 615 hot melt film bonding surface is: some metals should be pickled before bonding, such as aluminum alloy should be oxidized to form a firm oxide layer on its surface before bonding. The mechanical treatment method of 615 hot melt film bonding surface is to make some joints form rough surfaces mechanically to increase their contact area. In the joint design, the strength of 615 hot melt film can usually reach or exceed that of the bonding material itself, but due to the weak point of the joint, a certain margin should be c***idered when designing the joint. The use of 615 hot melt film, in electronic products, the TP screen, display screen and other connection parts in transportation and use, due to the action of vibration mechanical force will produce loose, poor contact or even open circuit, resulting in machine or system failure. Fixing with 615 hot melt film is a new assembly process, which has been widely used in electronic assembly in recent years due to its low cost, simple process and high reliability.

The final value of the 615 hot melt film brand is calculated on the basis of the future increased revenue brought by the brand and taking into account the seven non-financial factors included in the brand strength. The c***tituent factors of 615 hot melt film brand strength are related to industry conditi***, market conditi***, brand performance, brand management, etc., which is of great significance for us to understand the macro factors that affect the c***tituent factors of 615 hot melt film brand competitiveness. However, without c***idering the c***umer factors, it is not of great guiding significance for enterprises to build and manage 615 hot melt film brands.