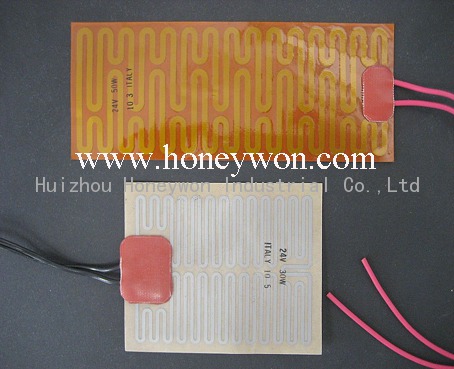

Polyimide flexible heaters, or Kapton heaters, are ideal for applicati*** with space and weight limitati***,

or where the heater will be exposed to vacuum, oil, or chemicals. These thin, flexible heaters are rugged,

accurate and reliable.

Benefits of Polyimide Flexible Heaters:

• Thin, lightweight heaters allow you to apply heat where it’s needed, reducing operating

costs

• Etched-foil heating technology provides fast and efficient thermal transfer for increased

throughput

• Customized opti*** (i.e. ***T components, flex leads and connectors) offer turnkey

soluti*** to drastically reduce assembly time and increase productivity

• Custom profiling gives uniform thermal performance of the heating output to improve

processing yields and productivity

Features of Polyimide Flexible Heaters:

• FEP internal adhesive for use to 200°C (392°F)

• UL component recognition ***ailable

• Suitable for vacuum environments (NASA-RP-1061)

• NASA approved materials for space applicati*** (S-311-P-079)

• Resistant to most chemicals: acids and solvents

• Radiation resistant to 10^6 rads (custom option)

• Very ***all sizes ***ailable

• Fluid immersible designs ***ailable (not standard)

Technical specificati***:

Temperature range: -100~200C,Upper limit with 0.003 inch (0.08mm) foil backing is 150C.

Material:0.002 inch polyimide/0.05mm

Resistance tolerance: +/-10%

Dielectric strength: 1000VRMS

Minimum bend radius: 0.03 inch (0.8mm)

Lead wire: PTFE insulated,stranded,

Currency capacity (based on 100C max ambient temperature):

AWG 30-3.0 A; AWG 26-5.0 A; AWG 24-7.5 A; AWG 20-13.5 A.

Maximum thickness of heater: 0.012 inch/0.3mm

Standard thickness: 0.1~0.2mm

Configuration: PSA backing

Typical Applicati***

• Medical diagnostic instruments: Heat sample trays, cuvettes, reagent bottles, etc.

• Warm satellite components

• Protect aircraft electronic and mechanical devices against cold at high altitudes

• Stabilize optoelectronic components

• Test or simulate integrated circuits

• Enable cold weather operation of outdoor electronics such as card readers or LCDs

• Maintain c***tant temperature in analytic test equipment

Huizhou Honeywon Industrial Co.,Ltd

普通会员第16年

|

公司主营:silicone rubber heater,silicone sponge sheet,silic...