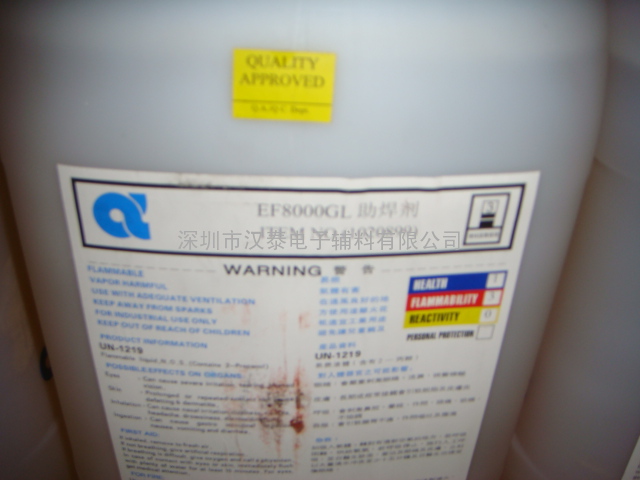

ALPHA EF8000GL Low Rosin, Pb-Free/Sn-Pb Capable W***e Flux

GENERAL DESCRIPTION

ALPHA EF-8000 GL is a rosin-containing flux designed to provide the attributes of excellent solderability and reliability in general and high-density boa*** in both Lead-Free and eutectic tin/lead processes. It is designed to h***e low bridging on bottom side QFP’s with 144-168 leads as well as superior performance in hole-fill and solderballing. Additionally, it provides good lead free solder joint co***etics with an evenly spread, tack free residue.

FEATURES & BENEFITS

Features for Pb-Free

• Good hole-fill dem***trated by >96% yield on 10 mil holes.

• Low bridging performance on connectors.

• Good micro-solder ball performance in Lead-Free applicati***

• Pin testable

• Specifically designed for use on Cu-OSP PCBs

Benefits:

• Excellent Lead-Free soldering performance on various board finishes.

• Evenly spread, tack free residue.

• Capable for high density as well as general purpose Lead-Free soldering processes.

• Can be used in Pb free or Sn/Pb processes

APPLICATION GUIDELINES

PREPARATION - In order to maintain c***istent soldering performance and electrical reliability, it is important to begin the process with circuit boa*** and components that meet established requirements for solderability and ionic cleanliness. It is suggested that assemblers establish specificati*** on these items with their suppliers and that suppliers provide

Certificates of Analysis with shipments and/or assemblers perform incoming inspection. A common specification for the ionic cleanliness of incoming boa*** and components is 5μg/in2

maximum, as measured by an Omegameter with heated solution.

Care should be taken in handling the circuit boa*** throughout the process. Boa*** should always be held at the edges. The use of clean, lint-free gloves is also recommended.

Conveyors, fingers and pallets should be cleaned. Alpha brand stencil cleaner is recommended for this process.

FLUX APPLICATION - ALPHA EF-8000-GL can be applied by spray or foam. When spray fluxing, the uniformity of the coating can be visually checked by running a piece of cardboard over the spray fluxer or by processing a board-sized piece of tempered glass through the spray and then through the preheat section.

HEALTH & SAFETY

Please refer to the Material Safety Data Sheet as the primary source of health and safety information. Inhalation of the volatilized flux activator fumes, which are generated at soldering temperatures, may cause headaches, dizziness and nausea.

|

Physical Properties

|

Typical Values

|

Parameters/Test

|

Typical Values

|

|

Appearance

|

Clear, Pale Yellow Liquid

|

pH, 5% v/v aqueous solution

|

3.1

|

|

SolidsContent,wt/wt

|

6.1%

|

Recommended Thinner

|

ALPHA 425

|

|

Specific Gr***ity @ 25°C (77°C)

|

0.81

|

Shelf Life

|

12 months

|

|

Acid Number (mg KOH/g)

|

26.5

|

IPC J-STD-004 Designation

|

ROL0

|

|

Flash Point (T.C.C.)

|

17°C

|

|

|

汉泰电子辅料有限公司是大陆地区***早从事***T工艺研究与制作的贸易商之一。公司具有多年电子行业从业经验,拥有一支高素质的***技术团队,专注服务于***T和PCB工艺制造焊接材料领域,主营阿尔法助焊剂、阿尔法锡膏、千住锡膏、阿米特锡膏、减摩锡膏、KOKI锡膏、铟泰锡膏、田村锡膏、***T贴片红胶、富士红胶、乐泰胶水、锡丝、锡条等***T焊接材料,欢迎来电咨询洽谈,我们将竭诚为您服务。

更多产品信息请登录http://