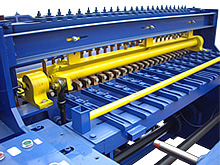

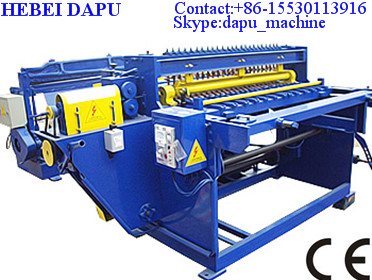

Steel Bar Mesh Welding Machine

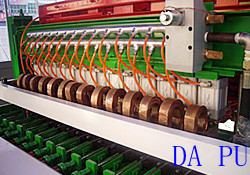

Description:This machine adopts synchronous control skill. The welding time and separate welding are controlled by computer based on Windows operation system, which makes the operation more intelligent zed. Mesh drawing system is controlled by servo-motor, which improves the precision of mesh opening size. Meanwhile the longitude and transversal spacing are adjustable. It simplifies the process that every tensile spring has to be changed when the welding wire diameter is different. You only need to change the pressure of welding point. Mesh falling system adopts BSHB31115 step-motor’s automatic falling part. The welding speed is fast and it is easy to learn. The mesh opening size is rather accurate; welding aperture could adjust randomly within range.

Usage: welding mesh for highway, railway, bridge, enclosure mesh, fencing, c***truction and so on.

Main parameter:

|

Wire diameter(mm) |

Width of mesh(m) |

Welding aperture(mm) |

Welding head |

Transformer (KW) |

Weight (T) |

|

5~12 |

2.5~3.0 |

100*100~300*300 |

24/26 |

100*12/ 100*13 |

10 |

Accessory parts:electric control cabinet; straightening and cutting machine (at least 2 sets)

Mesh drawing part (servo motor)