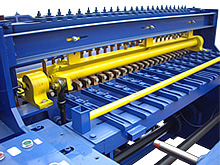

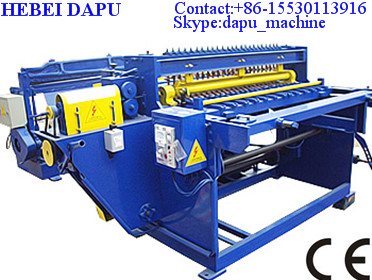

Steel Grating Welding Machine

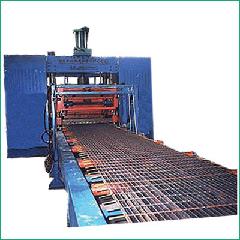

Description:Steel grating welding equipment is to finish flat bar and twisted (round, square) cross bar horizontal to be welded. This machine adopts technology of power electronic synchronous control, the welding time and separate-welding are combined by digital integrated circuits, the control precision are very accurate, operate ***oothly and the welding is very firm. The transfer parts used imported pneumatic element, it has characteristic of pressure uniformity, few malfunction and long service life. 24meters long, 3.8meters wide production line this, divided into person, welder person, cut according to process worker of end head person, finished product deposit engineering location, worker of material loading. Material loading adopt artificial loading(flat-rolled steel), horizontal pole(round steel) hands over the material automatically, then weld automatically, walk into automatically, it is cut location, worker of material, cut end head automatically, artificial to operate with draw material car hand over the finished product to the depositing area of the finished product to reach, then one is put automatically, pile up the platform to drop automatically, is full of until piling up the platform, operate and introduce the car artificially and put out the finished product one. The mesh drawing part adopts air cylinder and the welding head is hydraulic cylinder. Meanwhile, the post processing contains galvanization; cutting and shape them as customers’ need.

Usage:Welding mesh for platforms of petroleum, chemical industry, electricity, quay, municipal administration, environmental protection, national defence, etc.

Main parameter:

|

Wire diameter: flat iron:2.5*25~5*65mm(thickness*height) Twisted steel:5~8mm |

Width of mesh: ≤1m |

|

Length of mesh:6m |

|

|

Welding aperture: weft:30mm、50mm、100mm (adjustable) Longitude:30mm、40mm、50mm(if need adjusted, should change the mould) |

|

|

Transformer:150KW*2sets |

Production:60~100㎡/8hours |

|

Power supply:100KW(50m is better) |

Weight:4T |

|

Rated voltage:380V,50Hz,3Phase(according to the customer’s requirement) |

|

Accessory parts:electric control cabinet; bracket; straightening and cutting machine; twisting drawing machine; carbon dioxide welding machine; manual cutting machine; air compressor