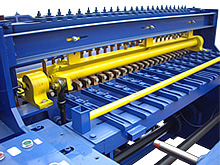

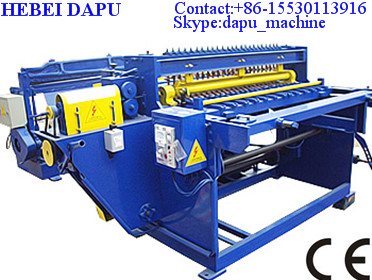

Steel Cage Welding Machine

Description:This machine adopts PLC control system、frequency control、touch screen control system and has a high degree of automatic. Processing molding speed, under the same conditi***, mechanical production is make artificially output 3 ~ 4 times, make the processing speed cost reduced greatly, the mechanical production, reduce 2/3 of the processing personnel. At the same time, it adopts mechanical system to produce steel bar cage, main steel and rolling bar welding uniformity, high precision, stable function. Stirrup need not lap, than manual work to s***e material and reduce the c***truction cost by 1%. Mobile disk and press enter all walk by using automatic walk, improve the degree of automation equipment. The mould can be replaceable in order to produce the different producti*** of different diameter, it is easy to learn and operat. The material is the ribber bar and gengeal bar. This machine needs the room of the workshonp: the length30m and the width 6m.

Usage: welding cage for c***truction, highway, railway, bridge and so on.

Main parameter:

|

Wire diameter: main steel:12~32mm (20/25/28mm common) |

Cage diameter:300~2500mm |

|

Rolling bar:6~16mm (10mm common) |

Length of cage: ≤18m |

|

Inner reinforcing bar:12~32mm(20/25/28 mm common) |

Capacity:10/10hours |

|

Rolling bar aperture:50~500mm (adjustable) |

|

|

Electric motor: 1):rotational motor:3KW*2sets; 2)drawing motor:3KW; 3)hydraulic station motor:5.5KW |

|

|

Wire feeding way: main steel: pre-cut and put by manual work Rolling bar: automatic feeding from coils |

|

Accessory parts:electric control cabinet; wire plate; straightening and cutting machine; inner reinforcing bending machine; carbon dioxide welding machine; general welding machine