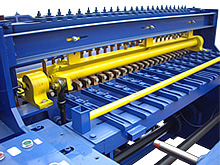

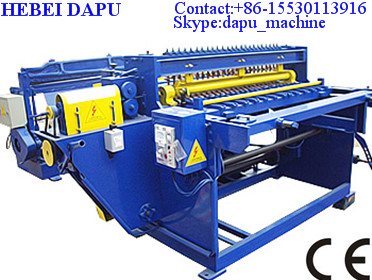

Pneumatic Wire Mesh Welding Machine

Description:This machine adopts electrical and electronic synchronous control technique, both welding time and separate-control welding is composed of digital and integrated electric circuit. This operation is accurate; it has stable function, firm welded point, without welded tracks. Not only welding speed is fast, but also it is easy to learn and operate. The machine is equipped with precise equipment for weft cutting and positioning, so the length of wefts is identical and regular, it is unnecessary to slice the side and adopts PLC automatic cutting. Drawing mesh system adopts elastic tension and opening positioning mesh, it is easy to regular mesh hole, and mesh opening size is rather accurate, welding aperture could adjust randomly within range. This machine adopts PLC control system with touch screen, has HMI.Automatic correction device on cylinder, forcibly even, nets of neat. According to the weft wire feeding way, JKA-1200Abelongs to automatic; JKA-1200B is semi-automatic.

Usage: welding mesh for enclosure mesh, building roof mesh and building etc.

Main parameter:

|

Model |

Wire diameter |

Width of mesh |

Welding aperture |

Number of warp |

Welding head diameter |

Weight |

|

JKA-1200A |

2.0~3.0mm |

1.2m |

50*50 |

25 |

18mm |

2.5T |

|

JKA-1200B |

2.5~4.0mm |

1.2m |

50.50 |

25 |

20mm |

3.0T |

Accessory parts:

JKA-1200A:Electric control cabinet; wire plate; wire coils*50; wire coil bracket; wire rolling machine; mesh repairing machine

JKA-1200B: electric control cabinet; wire plate; straightening and cutting machine; mesh repairing machine