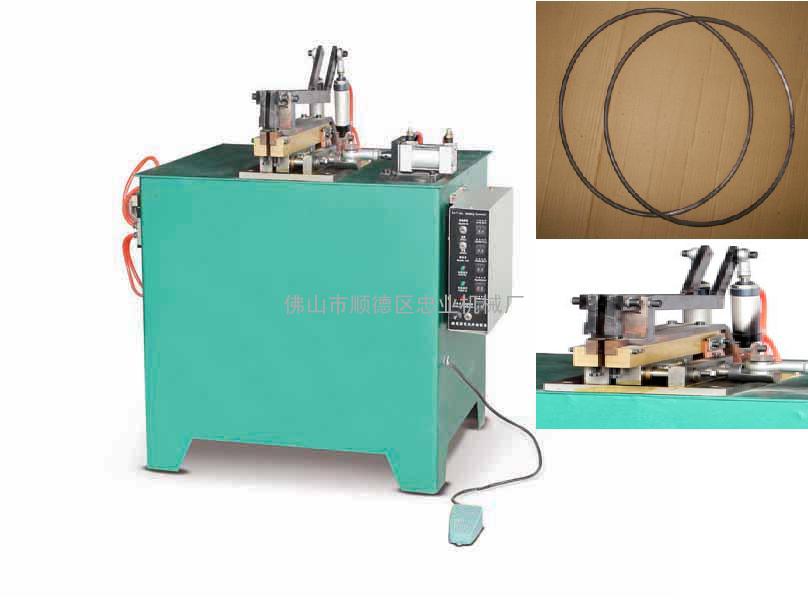

程控全自动单点弯形机

PROGRAM-CONTROLLED AUTOMATIC

SINGLE POINT BENDING TYPE MACHINE

适用于网篮筐和工业风扇网罩及类似铁线制品的骨架的自动焊接弯的机型。

本机控制系统采用日本三菱PLC,操作面板采用人机对话界面,界面为中英文(可选)显示,送料系统采用步进电机和伺服电机控制,具有速度快,精度高的特性;焊接系统采用单片机集成电路控制至系统,焊接系统采用双向可控硅控制等***技术,从而更能保证电流输出更为平稳可靠,并采用优化设计,高导电磁材料制作,致使设备在空载时损耗低,功率输出更强劲,稳定寿命更长。

将焊接好的内圈放入夹具模具中,再将铁线整卷放入铁线架上,取一头线头穿入弯型机的指定孔位上,按加工产品的规格设置好线长度、条数、折弯弧度、产品数量(可设可不设),开启开关弯型机可一次性自动完成线材调直、焊接、切断线材、折弯四个工艺,省去了传统制作工艺的调直机调直切断线材、单点机焊接及液压压型的三个繁锁工艺。

本设备操作简易,调试简易,此机还可当作线材调直机用,一机多功能,大大提高了生产效率。

Apply to nets basket and industrial fan nets cover and similar wire products of the skeleton of automatic welding machine bending.

This machine control system from Japan mitsubishi is used PLC, operation panel man-machine dialog interface, interface is both in Chinese and in English (optional) display, feed system adopts the stepping motor servo motor control and, with speed and precision of the character; Welding system USES the monolithic integrated circuit to control systems, welding system adopts the bidirectional thyristor control and other advanced techniques, and the more can guarantee the current output more stable and reliable, and optimize the design, high conductivity, the electromagnetic material production equipment in no-load loss, low power output more strong, stable to live longer.

Will good inner circle in welding fixture mold, then wire rolls into the wire rack, take a head through the thrum of the bending type machine designated a hole on the specificati*** of the products, according to the processing set line length, and bending article, number, number of product (radian set don't set), open switch bending machine can automatically complete the one-time type wire straightening, welding and cut off the wire, and bending four process, tell the traditional production technology of straightening machine straightening cut wire, single point welding machine and hydraulic pressure type three numerous lock process.

This equipment is easy to operate, debugging is simple, this machine can also be used as a wire straightening machine, one machine with multi-function, enhanced the production efficiency.