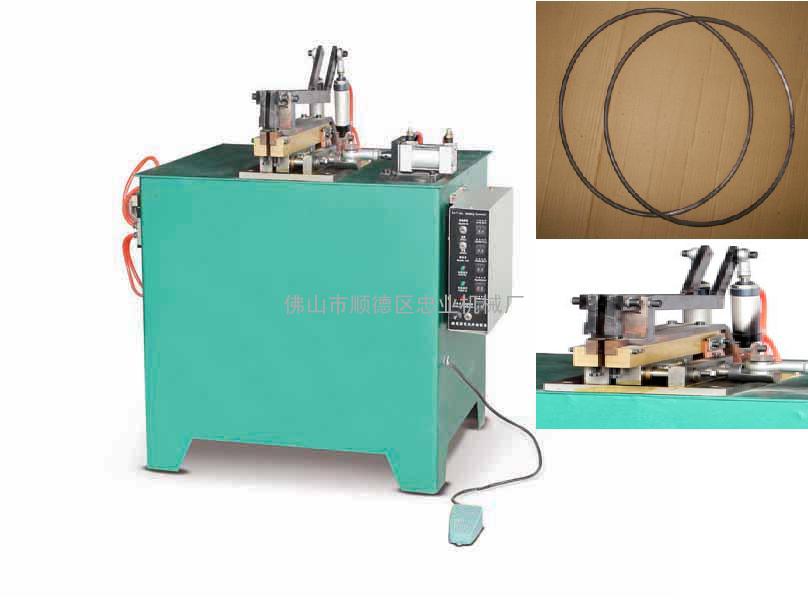

气动式点焊机系列PNEUMATIC TYPE SPOT WELDING SERIES

焊机装配合适的电极形式和控制器,可满足各种线类网篮制品,钢板网、管类制品等的加工制造。可进行碳钢、不锈钢、电镀钢及各种有色金属的线材、管材、板料,螺钉等到的点焊和排焊。

焊机采用高性能气动元件,主导轴及导向轴均采用镀铬光圆,传递压力灵活可靠,无虚位产生。焊接变压器采用环氧树脂浇注,次级内部通水强制冷却,并采用优化设计,高导磁材料制作,空载损耗低,功率输出强劲,稳定,寿命长;焊接控制器采用单片机集成控制系统,可选用高精度拔码式开关,输入预压,波头,焊接时间,保压,焊接电流等参数,并具有双脚踏,双脉冲,双电流控制功能,各式焊接控制器满足不同功能,可实现一机多用;焊接初级回路采用双向水冷可控硅控制,保证电流输出平衡,可靠。铜夹头采用半圆形或平台形,方便安装工装夹具。

Welding machine assembly appropriate electrode form and controller, can satisfy all sorts of line kind of a basket with netting on top products, steel nets, the kind of products processing manufacturing. For carbon steel, stainle teel, plating steel and all kinds of non-ferrous metal rods, tubes, the sheet metal, screw the spot welding and welding until the row.

Welding machine by high performance of pneumatic components, the dominant shaft and the direction for all use chrome axis light circle, transfer pressure flexible, no reliable absent produce. Welding transformer USES epoxy resin casting, subprime internal drainage systems, and forced cooling optimum design, high magnetic material production, low no-load loss, the output power is strong, stable, long life. Welding controller USES the monolithic integrated control system, can choose high precision code type switch out, the input preloading, w***e, welding time, the head pressure, welding current, and has the parameters such as feet tread, double pulse, double current control function, various welding controller meet different function, can achieve multi-usage; Welding primary windings adopts two-way water-cooled silicon-controlled rectifier control, ensure that current output balance, and reliable. Copper chuck using a semicircle shape or platform and easy installation fixture.