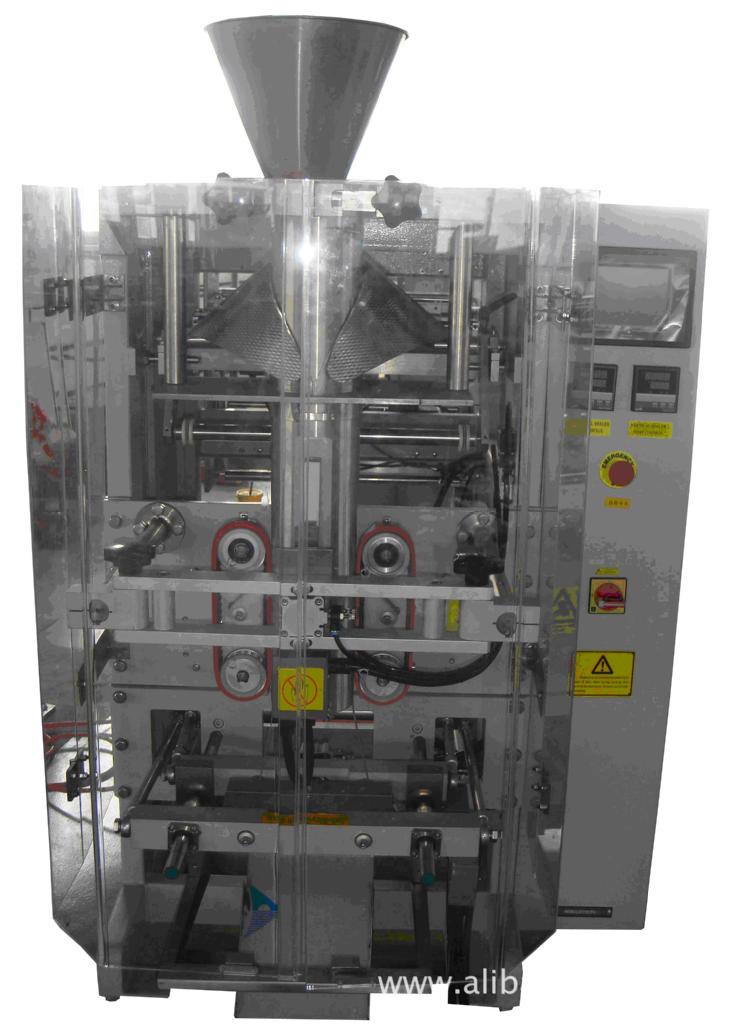

| QS-L420K自动颗粒包装机 主要性能和结构特点: - 采用伺服驱动系统,高精度、性能稳定等优点。

- 不锈钢开启式料箱清理方便。

- 配备安全防护,符合企业安全管理要求。

- 采用智能温控器,温度控制准确、保证封口美观平整。

- 采用PLC双拉纸结构走纸系统,封切位置均采用电机自动纠偏装置,超大显示触摸屏机构驱动控制核心,***大限度地提高了整个的控制精度、可靠性、和智能化程度。

- 本机与计量配套可自动完成产品计量、送料、充填、制袋、充气(排气)、日期打印、成品输送的全部包装过程,并自动完成计数。

- 设有故障显示系统,帮助及时排除故障。

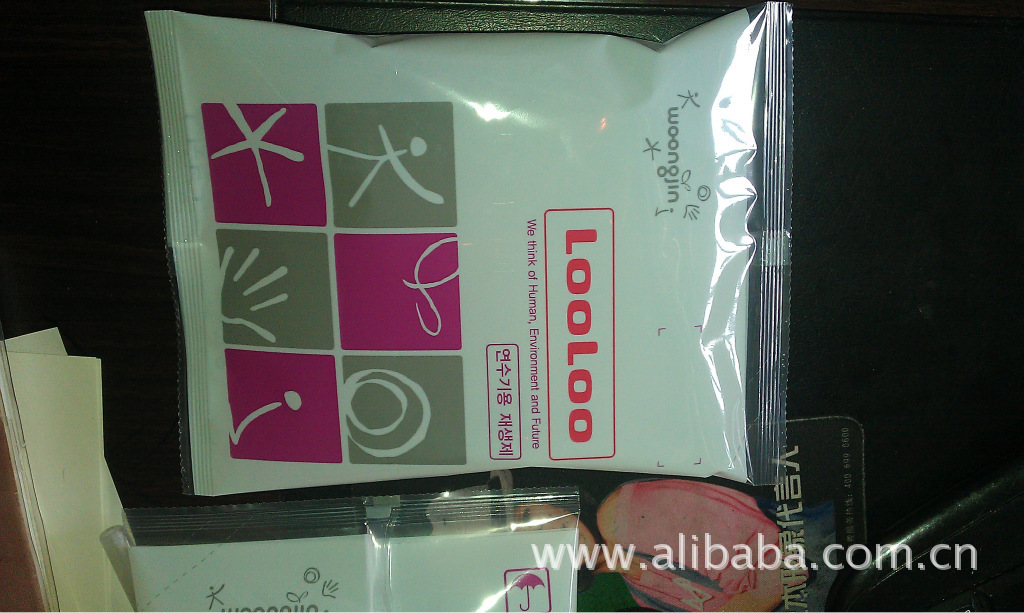

- 可根据客户需要制成枕形袋、打挂孔袋。

- 可选配装置有吸尘装置和插角装置。

适用范围: 适用计量包装那些不易流动或流动性差的粉粒物料。比如奶粉、米粉、奶茶粉、淀粉、蛋***、调味料等粉状物料的自动计量包装。 Main function and characteristic: - Use screw machine to complete measuring, filling and nitrogen charging.

- Use servo system with the merits of high precision and stable performance and so on.

- Easy for cleaning stainless steel hopper.

- Equipped with safety protection, conform to film’s safety management requires.

- Use intelligent temperature controlling machine to h***e accurate temperature control and ensure the artistic and neat seal.

- PLC double pulling film system, automatic rectifying equipment at seal and super touch screen control center maximize the whole machine’s control precision, reliability and intelligentized level.

- This machine completes the whole packing procedures of measuring, material transporting, feeding, bag-making, charging (exhausting), date printing and products transporting automatically as well as counting.

- H***e error indicating system helping to handle the trouble immediately.

- Make block bags and hanging bags according to customers’ different requirements.

- Dust suction device and gusseting device are optional to be mounted.

Application scope: Suitable for automatic measuring and packing uneasy flowing or bad liquidity powder, such as milk powder, rice powder, milk tea powder, amylum, albumen powder and fl***oring powder. 性能参数Performance parameter: 型 号Model | QS-L420K | 制袋尺寸Bag Size | L:80-300mm W:80-210mm | 包装速度Packing Speed | 10-85 bag/min | 包装范围Packing Range | 10-3000g | 电源功率Power | 220V,50-60Hz,3.0KW | 压缩空气用量 Compressed air c***umption | 6-8kg/m2, 0.15m3/min | 整机重量Machine Weight | 650-750kg | 外型尺寸Machine Size | L:1450×W:1000×H:2700mm |

*可根据客户要求定做背封、三边封、四边封!根据客户对误差及精度的要求适当将量杯式计量改为电子称计量,可根据客户对速度及包装重量的要求,适当配套电子称的数量!* |