The world’s largest passenger plane ever built, the Airbus A 380, completed its maiden flight in April 2005. Products from the Mulco-Europe EWIV-Group were also on board: self-tracking BRECO® timing belts, type ATK 10 K6, together with the respective pulleys. These polyurethane timing belts with high tensile steel cord tension members drive the two trolley lift systems of the “superjumbo”. The Jenoptik subsidiary, ESW – EXTEL SYSTEMS WEDEL Gesellschaft für Ausrüstung mbH, developed this transport system to ensure fast and efficient catering and supply on this jet, which is equipped with two full length passenger decks and one cargo deck.

During a flight on the Airbus A 380, more than 500 passengers need to be provided with everything usually supplied on board a passenger plane. Few realise what a great logistical achievement this is and what equipment is involved in transporting the catering trolleys from the lower on-board kitchen to the higher passenger decks.

It sounds simple and outwardly resembles a familiar passenger lift, but it is a high-tech system and involves highly sophisticated engineering. The supply concept for up to 555 flight passengers on the Airbus A 380 has to meet the highest demands, and offer both speed and maximum reliability.

It sounds simple and outwardly resembles a familiar passenger lift, but it is a high-tech system and involves highly sophisticated engineering. The supply concept for up to 555 flight passengers on the Airbus A 380 has to meet the highest demands, and offer both speed and maximum reliability.

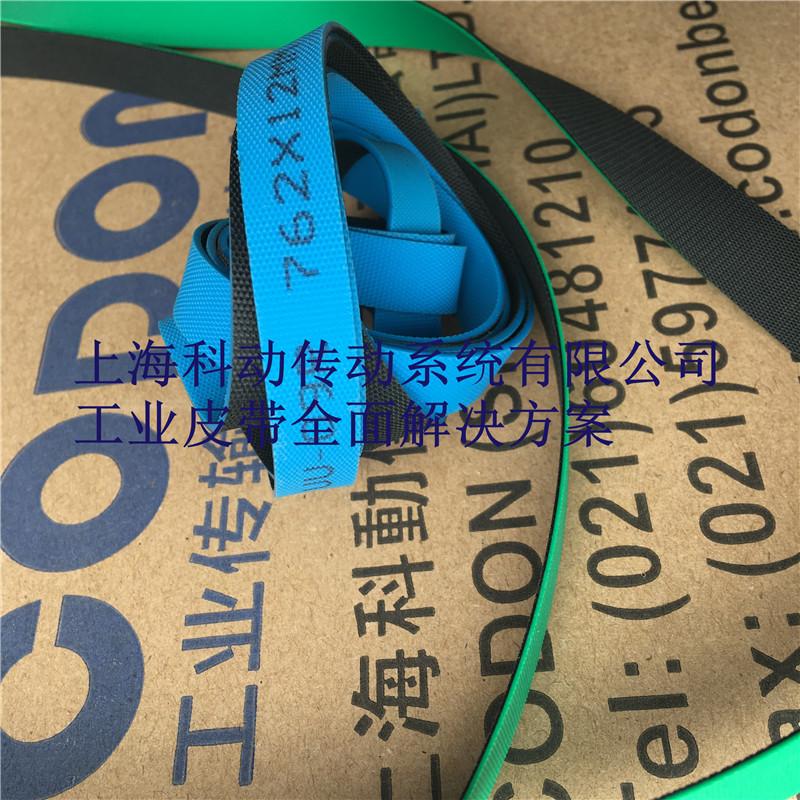

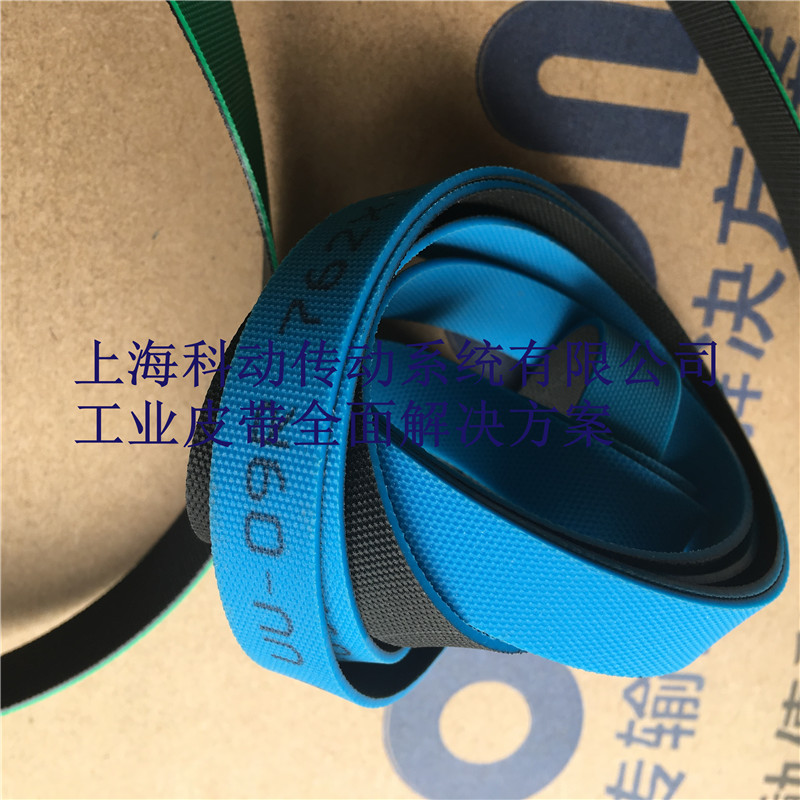

“The task involved differs c***iderably from the usual technical demands on our PU timing belt power tran***ission technology”, explains Jürgen Cremer, engineer and tran***ission spe***t at Wilhelm Herm. Müller GmbH in Hanover, which, as a Mulco partner in close cooperation with Breco Antriebstechnik Breher GmbH + Co. (Porta Westfalica) has been supporting ESW - Extel Systems Wedel since the development stage of the trolley lift system. And it was not just the geographical proximity of Hanover and Wedel, that led the team of 50 strong at ESW, headed by project leaders, Andreas Josenhans and Helmut Marquard, to choose BRECO® timing belts. “Airbus-Industries specified convenience, utmost reliability and minimal maintenance”, the two engineers explain. Therefore, the BRECO® PU timing belt was the first choice as a power tran***ission system because it meets both the high requirements and technical specificati*** for materials in aircraft c***truction, and features virtually noiseless running, wear resistance and excellent dimensional stability. Minimal maintenance is an important criterion because the lifts in the airbus are built encapsulated from the passenger areas. A nylon tooth facing on the PU timing belt contributes to its extremely quiet running characteristics and high wear resistance.

The extended time test, conducted on a lift for more than one and a half years, dem***trates how seriously the safety of the passengers and the flight personnel is taken. During this extended time test the lift moves up and down a distance of 2.94 metres one million times, carrying a weight of 240 kilos. It completes one journey in just under ten seconds.

The extended time test, conducted on a lift for more than one and a half years, dem***trates how seriously the safety of the passengers and the flight personnel is taken. During this extended time test the lift moves up and down a distance of 2.94 metres one million times, carrying a weight of 240 kilos. It completes one journey in just under ten seconds.

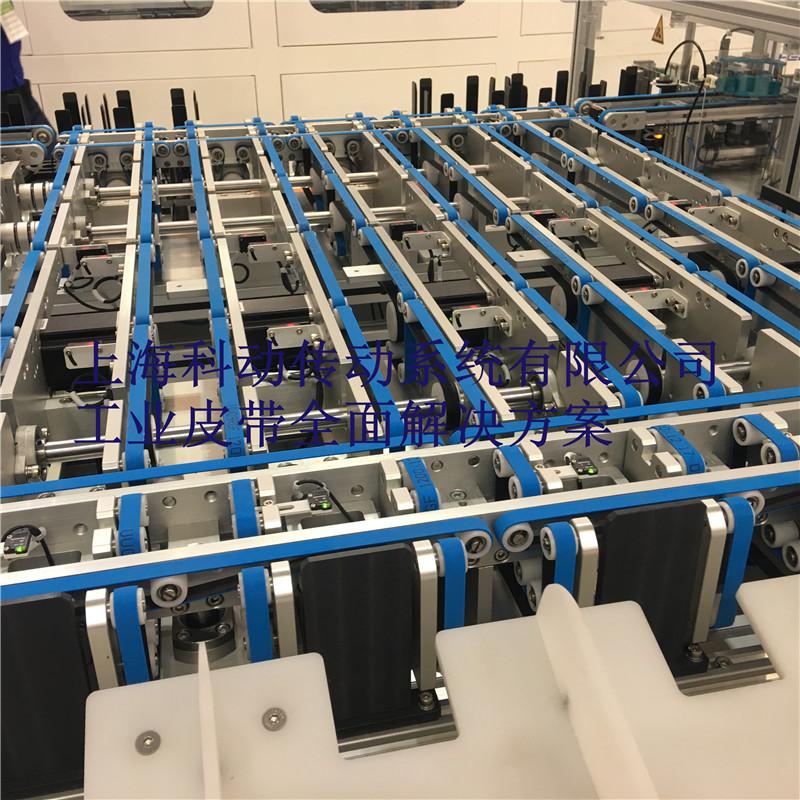

“Just imagine the additional mechanical and climatic forces acting upon the trolley lift system during flights, starts and landings with up to eight times the force of gr***ity”, says Dr. Klaus-H. Stölting, ESW-Vice President of Business Development and Communicati***, underlining the achievement of the entire team, and pointing out the light-weight c***truction of the trolley lift, which has an own weight of only 60 kilos. The aluminium mast c***ists of two half-shells running in resilient bearings. The endless timing belt runs over pulleys at the top and bottom of the mast and guides the bracket for the trolley. This c***truction is an example of how every excess gram of weight has to be ***oided in aircraft c***truction. A high-torque electric motor drives the redundantly designed system, which is equipped with braking and safety devices to prevent the free fall of the he***y trolley in the event of a malfunction.

ESW and Mulco gained extensive experience when they equipped all Lufthansa’s Airbus A 340-600 passenger planes with a similar trolley lift system. Among Lufthansa's priorities was the requirement to utilise the entire space inside the aircraft as economically as possible. So compartments used during the flight such as the on-board kitchen were located on the lower deck. On the Airbus A 340-600 the trolleys are transported from the on-board kitchen to the passenger deck by two separate lifts with half-size trolleys. These lifts are also equipped with 50 millimetre wide, 6250 millimetre long nylon tooth faced PU timing belts of the type BRECO® ATK10 K6.

BRECO.BRECOFLEX传动带.BRECOFLEX同步带.BRECO同步带工业皮带***解决方案

BRECOflex有限公司,公司成立于1989年与坚定承诺,我们的产品带入市场,以***,我们的客户服务和人民,我们的聘用,谁致力于满足客户的***高期望。我们的产品提供质量上乘,创新设计,以满足您今天的***具挑战性的要求和未来。我们的产品提供优良的品质和创新的设计功能,以满足您的***具挑战性的要求,在今天和未来。

BRECOflex公司,在聚氨酯同步带行业的***,套,的新的***更高的标准,***的产品designs.BRECO柔性有限公司,在聚氨酯同步带行业的***,******的产品设计新的***更高的标准。多元化同步带产品,金属滑轮和配件的科学设计和制造的精度和undeviating质量。

BRECOflex有限责任公司提供的******的***产品广泛一致。我们的聚氨酯同步带,滑轮,异型带,背衬Esband ®真是无穷无尽的梭织平皮带配件,广泛的产品范围。所有BRECOflex产品指的是在高品质。

BRECO.BRECOFLE***部位于德国生产同步带,运输V带,平面和特殊皮带,带轮和随之而来的组件。多样的应用领域的开发和生产特殊皮带。带背涂层的大量和***多样的造型挡板

1967年成立的BRECO由Rudolf Breher作为工具的制作和塑料加工企业。

1968年开发的生产工艺制造的热塑性聚氨酯同步带(专利)。BRECO成为的Mulco合资的成员。

1975年发展的BRECOFLEX®生产工艺(专利)。

1980年发展自跟踪皮带,同步带和紧张的成员在一个带结构的组合。

1985 BRECO开始生产同步带轮,并进一步组件。

1986年开发和专利保护的新同步带,类型审裁处。建立的BRECO GMBH公司Zahnscheiben的幼稚园。

1988年沃尔特·Rothermundt GMBH&CO KG从门兴格拉德巴赫成为我们的***个子公司。

1989 BRECOflex有限公司L.L.C.在美国成立。

1992年安东·克洛克Antriebstechnik公司成为本公司的附属公司。

1995年粘结剂磁S.A.R.L.从Gennevilliers的(法国),成为一间附属公司。

1997年开发和专利保护的弧形齿带英美***公司提供显着提高传输和运行性能。

1998年认证根据DIN EN ISO 9001认证,BRECO Antriebstechnik Breher GMBH&Co。和BRECO GMBH&CO。Zahnscheiben公斤。

2000年新开发的运输皮带ATN的专利申请。另一个生产车间的建设和就职典礼。

2001年ATN的模块化系统的进一步发展,推出ATN的同步带锁和ATN的V型槽。移至新建BRECO***。

2002年的ATN的CONNECT计算程序的开发。启动了高精度的轮廓与集成光学测量系统的焊接站。引进的两个长丝张力增强的运行性能的成员安排。

2003年推出集成导轨(BATK)的带弯曲的牙齿。推出的基于网络的计算工具和***CAD图纸的可能性产品目录。

2004年引进两个长丝张力成员卷取我们BRECOFLEX®同步带改进运行性能。

2005年推出新一代的BRECOFLEX®StandardPlus同步带,尤其是对高精度***应用。

2006年的BRECO®同步带简介锁定AT10 DC和T10 DC。

2007年一个新的生产车间建设,以扩大我们的能力。引进一个新的同步带,ATS15型输电和线性技术。我们的新BRECOFLEX®,AT3同步带发射功率较小的传输。

2008运动将在未来的地方- 期待我们进一步的创新产品的报价。

BRECO.BRECOFLEX传动带.BRECOFLEX同步带.BRECO同步带

大陆地区

技术选型电话:13391350298

销 售 热 线:13774455550 程先生

电 话:86-021-60481210

传 真:86-021-59774515

联系人:程亮(技术部)13774455550

E- mail: kdbelt@

地址:上海市青浦区新凤中路1743号

BRECO同步带折曲失效原因分析 |

BRECO同步带同步带产生噪音的原因和措施 |

BRECO同步带环形无缝聚氨酯同步带 系列:AT10 |

BRECO聚氨酯PU同步带 |

BRECO同步带双面齿同步带产品结构设计与原材科选择及胶 |

BRECO同步带带传动的类型、特点和应用 |

BRECO同步带规格及型号参数大全 |

BRECO同步带 |

BRECO同步带发展的重要的新工艺之一粘合工艺 |

BRECO同步带皮带伸长超过有效使用条件 |

BRECO同步带同步带介绍 |

BRECO同步带斜齿同步齿形带传动的应用 |

BRECO同步带斜齿同步带传动的应用研究 |

BRECO同步带的使用注意事项 |

BRECO同步带聚氨酯PU同步带产品介绍 |

BRECO同步带圆弧型同步带轮型号、特点、应用及材质简介 |

BRECO同步带双面齿形带的特点和参数 |

BRECO同步带双面齿同步带的特点 |

BRECO同步带的分类和功能 |

BRECO同步带同步带轮传动的特点介绍 |