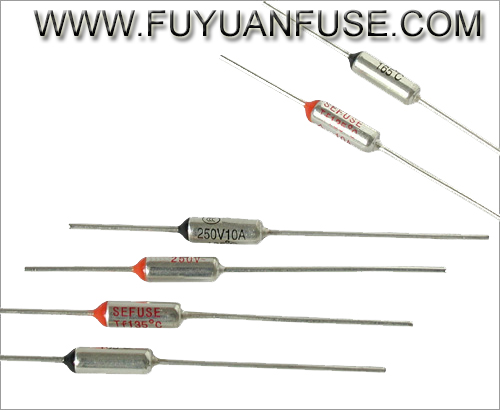

Physical map:

Description:

The lead free NANO2 Slo-Blo® fuse is RoHS compliant,Halogen Free and 100% lead-free. This product is fully compatible with lead-free solder alloys

and higher temperature profiles associated with lead-free assembly.The Slo-Blo® design has enhanced inrush withstand characteristics over the NANO2 Fast-Acting Fuse. The unique time delay feature of this fuse design helps solve the problem of nuisance “opening” by accommodating inrush currents that normally cause a fast-acting fuse to open.

Features:

• Lead-free and Halogen Free • Slo-Blo® • ***all size • Wide range of current ratings ***ailable • Wide operating temperature range

• Low temperature de-rating

Applicati***:

Secondary protection for space c***trained applicati***:

• Notebook PC • LCD/PDP TV • LCD monitor • LCD/PDP panel • LCD backlight inverter • Portable DVD player • Power supply

• Networking • PC server • Cooling fan system • Storage system • Telecom system • Wireless basestation • Game c***ole

• Office Automation equipment • Battery charging circuit protection • Industrial equipment• Medical equipment • Automotive

Electrical Characteristics for Series

| % of Ampere rating | OpeningTime |

| 100% | 4 hours, Minimum |

| 200% | 1 sec., Min.; 60 sec., Max. |

| 300% | 0.2 sec., Min.; 3 sec., Max |

| 800% | 0.02 sec., Min.; 0.1 sec., Max. |

Electrical Specificati*** by Item

| Ampere Rating (A) |

Amp Code | MaxVoltage Rating(V) |

Interrupting Rating |

Nominal Cold Resistance (Ohms) |

Nominal Melting I2t (A2sec) |

Agency Approvals | |

| 0.375 | .375 | 125 | 50 amperes @125 VAC/VDC PSE:100amperes @100 VAC |

1.5130 | 0.088 | x | |

| 0.500 | .500 | 125 | 0.7633 | 0.258 | x | ||

| 0.750 | .750 | 125 | 0.4080 | 0.847 | x | ||

| 1.00 | 001. | 125 | 0.2516 | 1.76 | x | x | |

| 1.50 | 01.5 | 125 | 0.1186 | 4.70 | x | x | |

| 2.00 | 002. | 125 | 0.0708 | 6.76 | x | x | |

| 2.50 | 02.5 | 125 | 0.0400 | 13.18 | x | x | |

| 3.00 | 003. | 125 | 0.0352 | 19.55 | x | x | |

| 3.50 | 03.5 | 125 | 0.0261 | 32.70 | x | x | |

| 4.00 | 004. | 125 | 0.0227 | 40.80 | x | x | |

| 5.00 | 005. | 125 | 0.0171 | 59.59 | x | x | |

Notes: - l2t calculated at 8ms. Resistance is measured at 10% of rated current, 25ºC

Temperature Derating Curve

Notes:

1. Derating depicted in this curve is in addition to the standard derating of 20% for continuous operation.

Example:For continuous operation at 75 degrees celsius, the fuse should be derated as follows:I = (0.80)(0.85)IRAT= (0.68)IRAT

***erage Time Current Curves

Soldering Parameters

| Reflow Condition | Pb – Free assembly |

| Pre Heat | - Temperature Min (Ts(min)) 150°C |

| - Temperature Max (Ts(max)) 200°C | |

| - Time (Min to Max) (ts) 60 – 120 secs | |

| ***erage ramp up rate (Liquidus Temp (TL) to peak | 3°C/second max. |

| TS(max) to TL - Ramp-up Rate | 3°C/second max. |

| Reflow | - Temperature (TL) (Liquidus) 217°C |

| - Temperature (tL) 60 – 90 seconds | |

| Peak Temperature (TP) | 260+0/–5 °C |

| Time within 5°C of actual peak Temperature (tp) | 20 – 40 seconds |

| Ramp-down Rate | 5°C/second max. |

| Time 25°C to peak Temperature (TP) | 8 minutes max. |

| Do not exceed | 260°C |

| W***e Soldering Parameters | 260°C Peak Temperature,3 seconds max. |

Product Characteristics

| Materials | Body: Ceramic Terminati***: Gold-plated Caps |

| Product Marking | Brand, Amperage Rating |

| Operating Temperature | -55°C to 125°C |

| Moisture Sensitivity Level | Level 1, J-STD-020C |

| Solderability | MIL-STD-202, Method 208 |

| Insulation Resistance (after Opening) | MIL-STD-202, Method 302, Test ConditionA (10,000 ohms minimum) |

| Thermal Shock | MIL-STD-202, Method 107, Test Condition B, 5 cycles, -65°C to 125°C, 15 minutes @ each extreme |

| Mechanical Shock | MIL-STD-202, Method 213, Test I:Deenergized. 100G’s pk amplitude, sawtooth w***e 6ms duration, 3 cycles XYZ+xyz = 18 shocks |

| Vibration | MIL-STD-202, Method 201: 0.03" amplitude, 10-55 Hz in 1 min. 2hrs each XYZ=6hrs |

| Moisture Resistance | MIL-STD-202, Method 106, 10 cycles |

| Salt Spray | MIL-STD-202, Method 101, Test Condition B (48hrs) |

| Resistance to Soldering Heat | MIL-STD-202, Method 210, Test condition B (10 sec at 260°C) |

Dimensi***

Packaging

| packaging Option | packaging Specification | Quantity | Quantity &packaging code |

| 12mm Tape and Reel | *** RS-481-2 (IEC 286, part 3) | 1000 | WR |