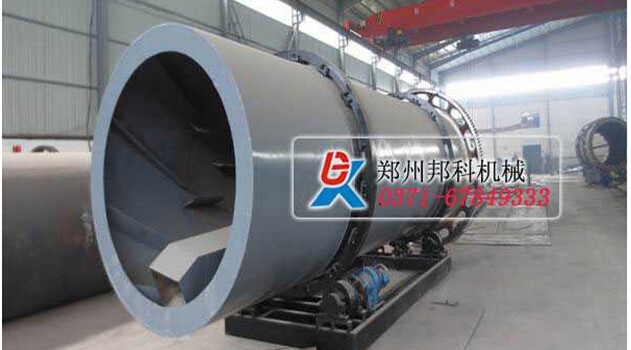

Bangke desulfurization gypsum dryer is widely used in drying gypsum,desulfurization gypsum,sulfur gypsum,fluorgypsum,phosphogypsum,titanium gypsum has significant effect.

Desulfurization Gypsum dryer introduction:

Desulphurization gypsum is short for termittent drum Gypsum powder Wok mainly c***ists of steel machine base, wok, frying pan which has scatter plate, stock guide,riding ring and tran***ission mechani***.Wok was installed on the furnace,so the furnace body can get the heat directly.Then the heat was passed to gypsum and fry the gypsum in this way.The wok machine use intermittent way to charge or discharge the material and timing frying.This machine is specialized developed for frying semi-hydrated gypsum powder and architectural gypsum podwer on the base of the technology of rotary and food wok machine.

Desulfurization Gypsum dryer Main Characteristics:

1.Can make use of the chemical gypsum ( desulfurization gypsum, phospho gypsum, etc..) to fry to β-semi-water gypsum powder directly;

2.Ensure the requirements of burning gypsum powder precise control frying time and temperature in the process.

3.Exit design of wok machine is reasonable, operation without dust pollution,

http:///product/Gypsum%ml

4.Intermittent feeding and discharging materials can pressure fire and shuYXown furnace, when open

furnace again, 3 minutes latter, it can be put into normal operation.

5.Equipped gas stove and boiling furnace supply the heating, the exhaust heat can be recycling

( boiling water or heated air).

Desulfurization gypsum dryer Working Principle

The heat source of dryer is from combustion devices. This dryer adopts direct flow heating method. So the material should be sent to the shell by the feed chamber and feed chute. After that the material will be pushed backward by the spiral shoveling plate. As the dryer is located with a tilt, the material flows to the end by the gr***ity and circumduction meanwhile it is shoveled repeatedly by the shoveling plate to the upper end then comes down c***tantly, forming an even curtain in the drum and exchanging heat fully with the hot current in the drum. With the material being raised and scattered again and again, the moisture is dried gradually. Finally it is dried totally.