立式虹吸乳化机

立式乳化机工作原理

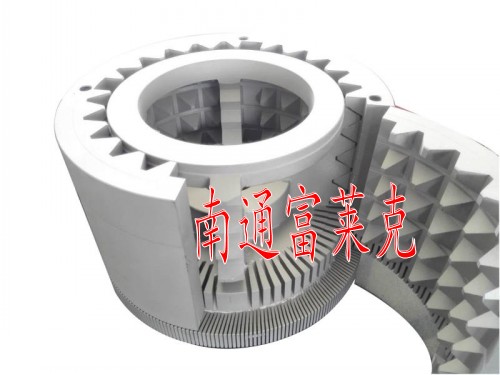

立式乳化机由机架、转定子、分散轮组成,在电机的驱动下,装在罐中部的小分散盘迅速开始工作,分散、切割,中上部的漂浮及部分添加剂,所形成的锅流正好增强了整体液料的循环起到了上下层同时分散、乳化、均质作用。以此同时按装底部乳化机头也在双向吸料,从中部和底部将物料吸入粉碎研磨区内,首先斜面刀片进行切割、分散,然后有研磨刀片进行粉碎、乳化。物料除承受剧烈的机动运动和液体剪切之外同时还承受挤压、撞击、撕裂和摩擦等,整个工作过程物料不断循环上下翻滚,在精密的转子和定子及分散盘的配合下,使物料微粒在极短的时间内很快被撕破,粉碎成亚微米细度,达到分散、乳化、均质的目的。

立式乳化机技术参数

型号 DSL2 DSL4 DSL7 DSL11 DSL15 DSL18 DSL22 DSL30 DSL37 DSL45

功率kw 2 4 7.5 11 15 18 22 30 37 45

转速r/min 2950 2950 2950 2950 2950 2950 2950 1440 1440 1440

定子外径mm 89 104 120 140 158 180 210 250 280 320

混合桨叶mm 80 100 110 130 148 170 200 240 270 310

高速分散盘mm 80 100 110 130 148 170 200 240 270 310

轴长mm 622 838 1130 1200 1280 1300 1370 1500 1700 2000

容积㎥ 15-100L 50-200L 0.09-1 0.1-1.5 0.2-2 0.3-2 0.5-3 0.8-5 1.5-8 3-20 FLECK Vertical Kettle Bottom Emulsification Machine

Operating principle of FLECK vertical kettle bottom emulsification machine

FLECK vertical kettle bottom emulsification machine is made up of frame, the stator and scattered round.Under the driven of motor,***all scattered dish in the middle of the pot quickly began to work.Vortex formed by the floating and some additives in the upper part, exactly enhance the overall liquid circulation,make the lower and higher level process dispersion, emulsion, homogeneous function at the same time. At the same time, in the bottom ,the emulsifying machine head is in a double absorption of material, from the middle and bottom inhaled the material into crushing grinding zone. Firstly,the bevel blade proceed cutting and dispersing, then a grinding blade grinding, emulsifying.Materials in addition to withstand severe motor sport and liquid shear also bear extrusion, impact, friction and tear ,the material cycle rolling up and down in the whole working process.With the cooperation of the rotor, stator and dispersion plate ,material particles are quickly torn and crushed into submicron fineness in a very short period of ached the purpose of dispersion, emulsion, homogeneous.

Technical parameter of FLECK vertical kettle bottom emulsification machine

型号 DSL2 DSL4 DSL7 DSL11 DSL15 DSL18 DSL22 DSL30 DSL37 DSL45

Motor power kw 2 4 7.5 11 15 18 22 30 37 45

Revolving speed r/min 2950 2950 2950 2950 2950 2950 2950 1440 1440 1440

Stator outer diameter mm 89 104 120 140 158 180 210 250 280 320

Mixing arm mm 80 100 110 130 148 170 200 240 270 310

High speed dispersion platmm 80 100 110 130 148 170 200 240 270 310

Axial length mm 622 838 1130 1200 1280 1300 1370 1500 1700 2000

Capacity㎥ 15-100L 50-200L 0.09-1 0.1-1.5 0.2-2 0.3-2 0.5-3 0.8-5 1.5-8 3-20