MEGADYNE,DONGIL环形无缝皮带,UNITTA EV8YU橡胶同步带

CLASSIFICATI***:

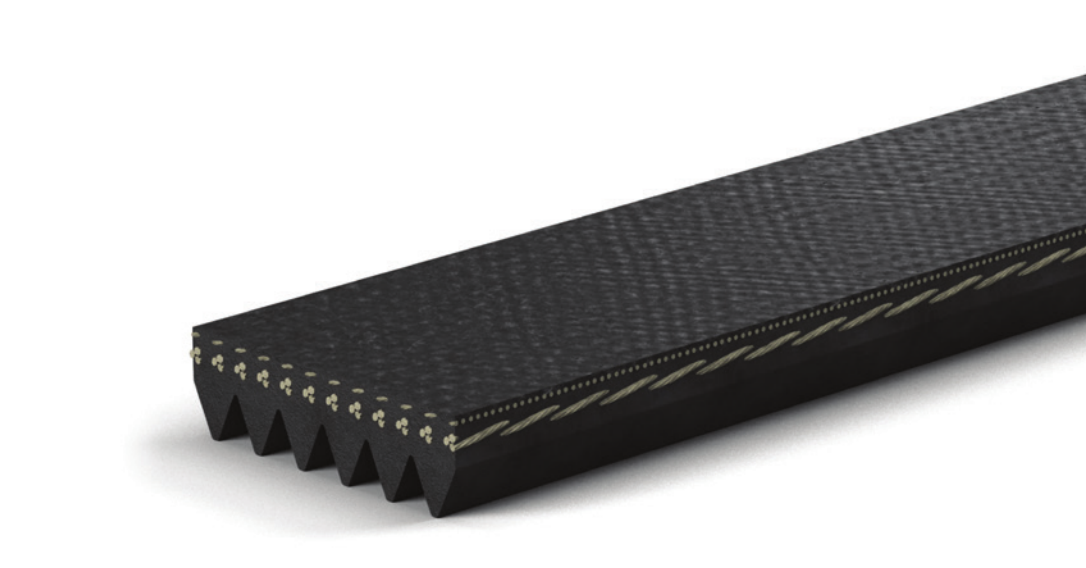

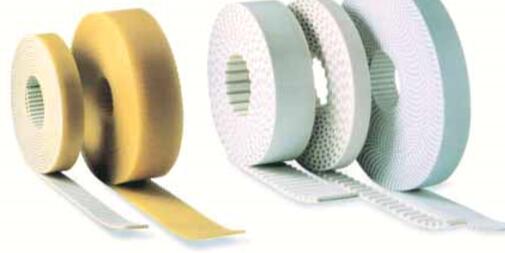

Megalinear Timing Belts are manufactured in thermoplastic polyurethane, with single parallel steel co***. This type of belts, developed by our Research & Development, offers good running characteristics and high traction loads. They are especially suited for power tran***ission and conveying with high loads and speeds. The addition of a nylon coating on the teeth during production enhances the running properties for specific applicati*** and reduces the noise due to a lower frictional coefficient. An extra thickness of special coating is also possible on the back of the belt offering extra protection against aggressive or he***y products.

1) The body of the belts is white thermoplastic polyurethane 92 ShA, characterized by high levels of wear resistance even in the presence of shock and surge loading.

2) High strength S and Z parallel zinked steel tension members allow high breaking load and extremely low elongation. The combination of these high grade materials improves belt performances which can be summarised as follows: • exceptional resistance to abrasion and tooth shear • low coefficient of friction • high flexibility • ozone and temperature resistance (-30 °C / +80 °C) • oil, grease and gasoline resistance

BODY MEGADYNE belts are manufactured with white thermoplastic Polyurethane 92 ShA as standard. Special compounds (different hardnesses, special properties) are ***ailable on request. Here under some PU characteristics:

Water No problem in normal or sea clean water, at room temperature. Over 60 ºC there is a fast decrement of breaking strength. Acids In acid diluted proporti***, at room temperature, this PU is moderately attacked. In high concentration acid soluti***, this PU has a very short lifespan. Over 50 ºC, acids are always dangerous for Thermoplastic PU. Alkalis In alkalis diluted proporti***, at room temperature, this PU is moderately attacked. In high concentration acid soluti***, this PU has a very short lifespan. DONGIL Over 50 ºC, acids are always dangerous for Thermoplastic PU. Solvents Thermoplastic PU is insoluble in the greater part of solvents. Only the very polar solvents (same as tetrahydrofuran, dimethylformamide, n-methylpyrrolidone) can dissolve or tight damage PU. The Esters or the Ket*** (same as ethyl acetate or methylethylketene) can usually produce a bulge, decreasing mechanical characteristics. The Hydrocarb*** aromatic and the Hydrocarb*** aliphatic produce very high bulge. All the effects increase by increasing temperature. Oils PU has a high resistance to mineral pure oils (lubrificants, engine oils, combustible oils). Usually, high performance syntetic oils, due to special additives contained, can be incompa

1