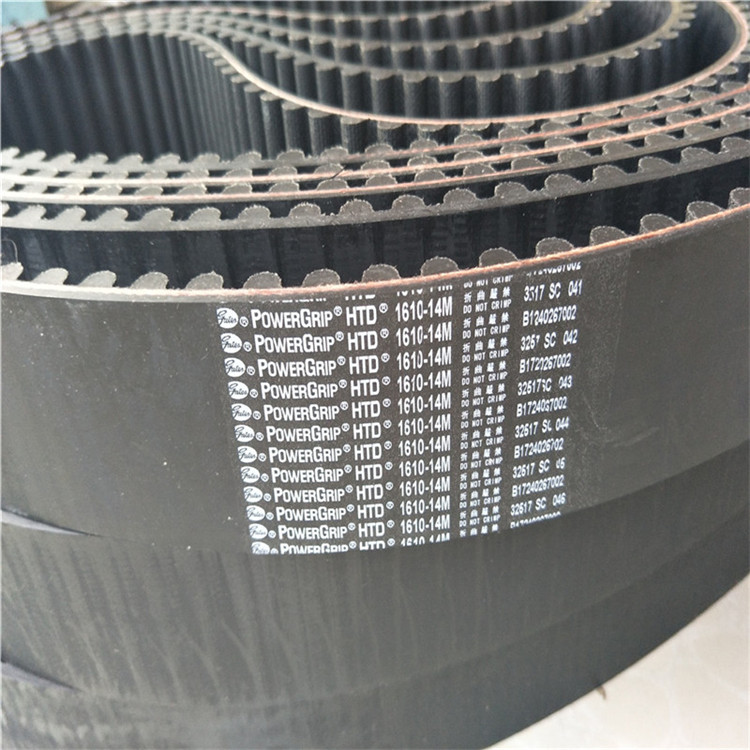

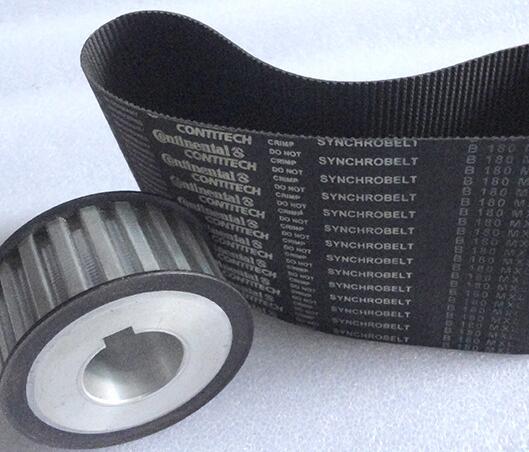

FORBO SIEGLING 美国GATES Ultrapower AG KC高强度三角带,BRECO SYNCHROFLEX同步带

Ultrapower AG KC is c***tructed specifically for those drives where a clutching function is essential to successful operation. Compounded to provide maximum durability during the clutching phase of operation, the KC's envelope, aramid fiber tension members and low profile design provide extended service life and superior flexibility to handle idler and reverse bend drive configurati*** typical of many power equipment applicati***.

1、BRECO KC envelope is designed specifically to handle the wear and tear of clutching applicati***. Bias cut, cross woven fabric is oil and heat resistant

2、Aramid fiber tensile co*** tran***it up to 20% more horsepower than traditional polyester c***truction. High modulus co*** placed just above the neutral axis resist elongation, reducing or eliminating retensioning or expensive take-up mechani***s

3、The body of the KC is formulated to reduce heat buildup for a cooler running, longer lasting belt. The BANPRENE compound balances firmness with flexibility to maintain cross sectional uniformity.

Where clutching is not a requirement, select the Ultrapower AG K c***truction which has the same internal components as the KC design, only with a rubber impregnated fabric cover.

美国GATES Metric V-Belts:

In addition to belts manufactured to RMA (Rubber Manufacturers Association) standa***, BANDO produces belts to European standard DIN 7753 and ISO4184. These standa*** are based on the metric system of measure and h***e different cross section designati***. The Narrow Wedge profile allows for higher speed ratios, shorter center distances and more compact drives. They are direct replacements for belts on imported machinery and on domestic equipment for export.

1、 Oil and heat resistant bias cut envelope protects the belt's inner components against dirt, oil and heat. The bias cut BANPRENE impregnated fabric provides lateral stability while permitting axial flexibility for operating around ***all pulley diameters.

2、High density polyester tension members treated for fatigue and elongation resistance minimize maintenance costs.

3、FORBO SIEGLING compression section maintains tension member cross section uniformity while remaining flexible enough to reduce heat build up - one of the primary causes of premature belt failure.