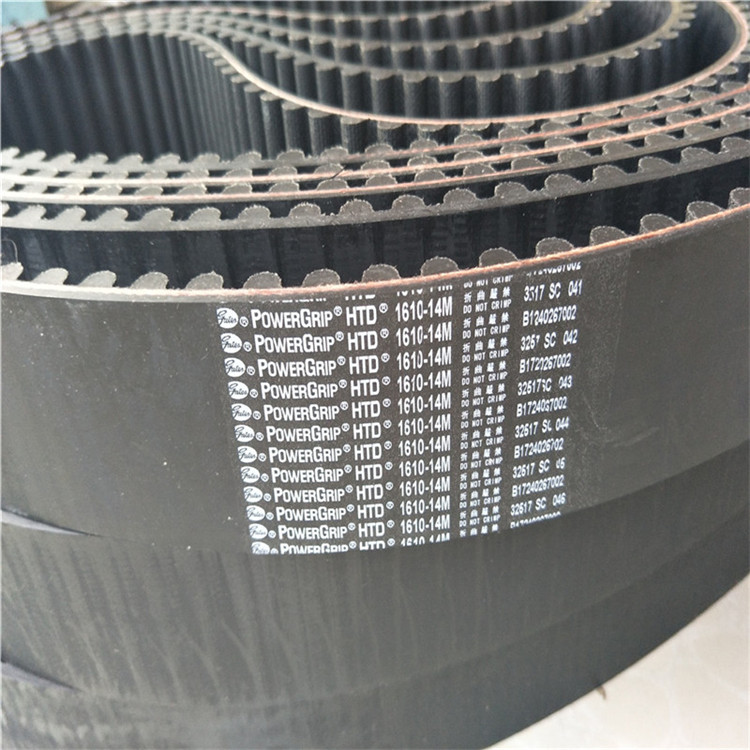

FORBO SIEGLING Synchro-Link Timing Belts,GATES,BRECO,MULCO齿型技术研究

When synchronization of the driveN and driveR speed is required, Synchro-Link Timing Belts give unsurpassed efficiency, economy and performance and are ***ailable in both inch (RMA) and metric dimensi***. GATES timing belts offer these advantages:

BRECO Popular Profiles – ***ailable in the high torque, low noise STS profile, the widely used HT curvilinear profile and the traditional Trapezoidal profile.

Non-Slip, Positive Performance — Belt-pulley compatibility and close manufacturing tolerances assure that belt teeth mesh precisely with pulley grooves for c***tant output speed without skipping, vibration or speed variation.

Extremely energy efficient - Studies by the US Department of Energy h***e found that synchronous belt drives are over 99% energy efficient, leading to lower operating costs.

1、 Low Maintenance/Economical Operation — Because timing belts do not require re-tensioning and, unlike gears or chain, require no lubrication, they are ideal for applicati*** where maintenance is difficult and downtime is costly.

2、Wide Range of Load Capacities and Speeds — Design versatility makes timing belts the right choice for a variety of applicati***.Speeds can range from 1 to over 10,000 RPM;load carrying capacity can vary from fractional to hundreds of horsepower.

3、 Space and Weight S***ings — Drives are compact because pulleys are ***all and center distances are short. Per horsepower tran***itted, timing belts weigh only a fraction of alternative methods.

4、Clean, Quiet Operation — Noise and vibration are kept to a minimum. Clean operation is ideal for contamination sensitive machines.

FORBO SIEGLING Synchro-Link Super Torque Timing Belts:

GATES Due to its high power tran***ission capabilities, quiet, ***ooth running tooth meshing qualities, energy efficiency and reliability, the STS tooth profile is widely recognized by automotive design engineers as the preferred belt for overhead cam applicati*** in most late model cars and trucks. These same qualities make this generation of synchronous belts ideal for today's high performance industrial applicati***.

As the tooth meshes with the pulley groove, the cord lay forms an almost true circle, minimizing the cantilever effect on the co***, resulting in reduced bending fatigue and longer service life

***ooth tooth engagement and direct contact of the belt tooth and the pulley groove enable the belt to run quietly, even at high speeds