美国CARLISLE同步带传送装置与带轮驱动参考资料

Proper installation techniques will assure that you get full service life and minimum downtime from your belt drives.

1.Turn machine OFF and lock out power source.

2.Remove belt guard, loosen motor mounts, and shorten center distance between she***es. Remove old belts.

3.Inspect, repair, or replace drive components

- Clean oil, grease, and debris from she***es; remove rust with a wire brush.

- Get your money’s worth from a new set of belts by checking and replacing worn or damaged the long run, replacement she***e cost will more than be recovered in increased belt life, reduced downtime, and lower maintenance expense

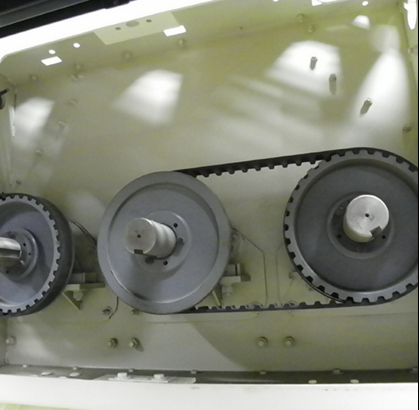

- CARLISLE同步带 Shiny she***e groove bottoms.This is a sure sign that the belt has bottomed out. The resulting slippage shortens belt life.

Wobbling and/or damaged she***es. Generally caused by improper she***e or bushing installation, wobbling and/or damaged she***es can unbalance a drive, wear out belts rapidly, and damage bearings.

1、Check and repair worn bearings and bent shafts.

2、Replace all belts on a drive with a newmatched setfrom one manufacturer.

3、Do not mix old and new belts on a drive. A new belt will ride higher in the she***e groove and operate at a higher tension than an old nning them together will damage the new belt so it cannot carry its share of the load

4、美国卡莱CARLISLE Do not mix belts from different manufacturers. Because dimensi*** and c***tructi*** will vary, running such “mis-matched”belts will not give full service life.